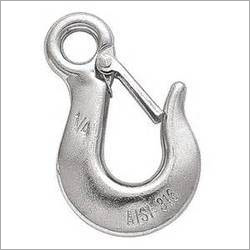

Steel Lifting Hook

MOQ : 10 Pieces

Steel Lifting Hook Specification

- Product Type

- Lifting Hook

- Material

- Alloy steel

- Usage

- Industrial lifting and hoisting

- Application

- Construction, rigging, material handling

- Size

- Customizable, standard sizes available

- Weight

- Depends on size (ranges from 0.5 kg to 5 kg)

- Color

- Silver/Grey

- Tensile Strength

- High tensile strength, up to 850 MPa

- Capacity

- 500 kg to 10 tons (varies by size)

- Feature

- Corrosion resistant, heavy-duty, durable design

- Shape

- Forged hook with safety latch

- Packing Type

- Carton box or wooden case

- Hardness

- 38-42 HRC

- Latch Type

- Spring-loaded safety latch

- Safety Factor

- Minimum 4:1

- Hook Opening

- Varies by model (from 18 mm to 80 mm)

- Operating Temperature Range

- -20°C to 200°C

- Surface Finish

- Galvanized or painted

Steel Lifting Hook Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- Piece

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- DEPEND ON PRODUCT

- Main Domestic Market

- All India

About Steel Lifting Hook

We provide Steel Lifting Hook that is basically used for lifting material efficiently. This product is designed by using the optimum quality steel material that makes it highly strong and durable. It has an ability to withstand heavy load easily. Our offered product is highly known for its rugged design, fine finish, optimum strength or lightweight. Provided product is precisely polished by anti-corrosive powder that makes it rust proof. This Steel Lifting Hook is also available in different sizes according to the needs of our valuable patrons.

Versatile Industrial Performance

Our steel lifting hooks cater to industrial needs, accommodating diverse applications in lifting, rigging, construction, and material handling. They are available in standard and custom sizes, ensuring an optimal solution for varying operational requirements. With robust build quality and adaptability, these hooks are a reliable asset for any demanding workplace.

Safety and Reliability Assured

Prioritizing user safety, each hook is constructed with a spring-loaded safety latch and adheres to a minimum 4:1 safety factor. The hardened alloy steel, ranging between 38-42 HRC, promises remarkable durability and resistance under high loads, while corrosion-resistant finishes (galvanized or painted) ensure long-term reliability, even in challenging environments.

Easy Handling and Wide Availability

We offer flexible packaging options, such as carton boxes or wooden cases, to accommodate bulk orders from distributors, traders, and wholesalers across India. Clear labelling and robust packaging facilitate smooth inventory management and transport, making procurement and deployment straightforward for large-scale projects.

FAQs of Steel Lifting Hook:

Q: How should I select the appropriate steel lifting hook for my application?

A: Choose the hook based on your load requirements (capacity from 500 kg to 10 tons) and dimensions needed (hook opening from 18 mm to 80 mm). Consider the working environment, including temperature and necessary corrosion resistance, to ensure optimal performance and safety.Q: What safety features are included with these lifting hooks?

A: Each hook is forged with a high safety factor (minimum 4:1) and fitted with a spring-loaded safety latch to prevent accidental disengagement during operation. The alloy steel build and robust latch system provide a secure solution for industrial lifting.Q: When should I inspect or replace my steel lifting hook?

A: Inspect hooks before each use for wear, deformation, or corrosion. Replacement is recommended if the latch mechanism malfunctions, the hook shows signs of cracking, excessive wear, or has been shock-loaded beyond its rated capacity.Q: Where can these hooks be used?

A: These hooks are designed for industrial environments such as construction sites, warehouses, shipyards, and manufacturing plantssuitable for rigging, material handling, and heavy lifting applications where durability and safety are critical.Q: What is the process for ordering these hooks in bulk?

A: Bulk orders can be placed through authorized distributors, suppliers, or traders across India. Specify the required sizes, capacities, packing type (carton or wooden case), and finish (galvanized or painted) when ordering to ensure accurate fulfillment.Q: How does the surface finish benefit the hooks longevity?

A: The galvanized or painted finish provides excellent resistance against rust and corrosion, prolonging the lifespan of the hook even in harsh industrial or outdoor environments. This ensures continued safety and reduces long-term maintenance costs.Q: What are the advantages of using a forged hook with a spring-loaded latch over standard hooks?

A: Forged hooks offer higher tensile strength and durability, while the spring-loaded safety latch ensures continuous securement of the load. Together, these features enhance operational safety and reduce the risk of accidental load drops.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Lifting Equipment Category

Webbing Sling

Price 700 INR

Minimum Order Quantity : 1 Piece

Usage : Lifting and material handling

Capacity : 500 kg to 10,000 kg (varies by sling size and type)

Feature : Flexible, high strength, nonabrasive, corrosion resistant, conforms to EN and IS standards

Material : 100% polyester webbing

Wire Rope Sling

Price 1000 INR

Minimum Order Quantity : 1 Piece

Usage : Lifting and Rigging Operations

Capacity : Varies from 1 Ton to 50 Ton and above

Feature : Abrasion Resistant, Flexible, Durable, Corrosion Resistant

Material : Steel (Galvanized or Ungalvanized)

|

SHIVAM ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry