Wire Rope Sling

MOQ : 1 Piece

Wire Rope Sling Specification

- Product Type

- Wire Rope Sling

- Material

- Steel (Galvanized or Ungalvanized)

- Usage

- Lifting and Rigging Operations

- Application

- Construction, Marine, Mining, Industrial Loads

- Size

- As per requirement (Customizable, typically 6mm - 50mm Diameter)

- Weight

- Variable based on length and diameter

- Color

- Natural Metallic Grey

- Tensile Strength

- High Tensile (1770 N/mm to 1960 N/mm)

- Capacity

- Varies from 1 Ton to 50 Ton and above

- Feature

- Abrasion Resistant, Flexible, Durable, Corrosion Resistant

Wire Rope Sling Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- Piece

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- DEPEND ON PRODUCT

- Main Domestic Market

- All India

About Wire Rope Sling

For lifting heavy material in a safe and easy way, we provide Wire Rope Sling to our valuable customers. We use the best quality metal wire for making this rope extremely strong and durable. It is mainly fitted in pulleys and lifters for industrial lifting applications. Because of its optimum strength or excellent load carrying ability, the offered product is highly appreciated among our valued clients. This Wire Rope Sling is available in different sizes as per the requirements of our clients.

Fully Customizable for Diverse Operations

Whether the project requires specific lengths, diameters (typically ranging from 6mm to 50mm), or special end fittings, Wire Rope Slings can be tailored to exact requirements. Their adaptable design ensures compatibility with various lifting tasks in sectors like construction, marine, and mining, providing the flexibility needed for both standard and unique applications.

Reliable Safety and Durability Features

Engineered with a safety factor of 5:1 or higher, these slings prioritize operator safety. They are constructed from high tensile steel and comply with international standards, ensuring longevity and consistent performance even in demanding environments. Options for abrasion resistance, corrosion resistance, and temperature tolerance extend their service life.

Wide Range of Applications and Packaging Options

Wire Rope Slings are ideal for lifting and rigging in construction sites, shipyards, mines, and heavy industries. They come packaged as coils or reels or as specified by the client to ensure easy handling and storage. Their load capacities range from 1 Ton up to over 50 Tons, catering to both light and heavy lifting needs.

FAQs of Wire Rope Sling:

Q: How are Wire Rope Slings customized for specific applications?

A: Wire Rope Slings are custom-made based on the clients requirements for length, diameter (typically 6mm to 50mm), end fittings (such as thimbles, eyes, hooks, shackles), and construction type (6x19, 6x36, 7x19, or as specified). By providing your precise specifications, you can ensure the sling matches your applications load, environment, and safety needs.Q: What standards and safety measures do these slings comply with?

A: These slings adhere to national and international standards including IS, EN, ASME, and DIN, or other specified norms. They feature a minimum safety factor of 5:1, ensuring high reliability during lifting operations. Every sling is designed and tested as per the manufacturers stated breaking load and safety certifications.Q: Where are Wire Rope Slings commonly used?

A: Wire Rope Slings are widely employed in construction, marine operations, mining, and various industrial lifting and rigging applications. Their robust construction and adaptability make them suitable for both indoor and outdoor heavy load handling.Q: What is the process for selecting the right Wire Rope Sling?

A: Choosing the correct sling involves determining the load weight, required length, environmental factors (like temperature or corrosion exposure), and selecting suitable end fittings. Consulting with a distributor or supplier ensures you get a sling that meets both operational demands and compliance standards.Q: How do Wire Rope Slings benefit lifting operations?

A: These slings provide excellent tensile strength (1770 N/mm to 1960 N/mm), high abrasion and corrosion resistance, and flexibility, which enhances lifting safety and reduces downtime. Their durability and compliance with safety standards minimize risks and deliver long-term value to users.Q: When should the slings be replaced or inspected?

A: Regular inspection is essential before each use, focusing on wear, corrosion, broken wires, or deformation. Replacement should occur if there are visible signs of damage or when the sling fails to meet safety standards after inspection, ensuring safe lifting practices at all times.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Lifting Equipment Category

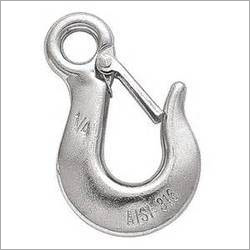

Steel Lifting Hook

Price 250 INR

Minimum Order Quantity : 10 Pieces

Capacity : 500 kg to 10 tons (varies by size)

Application : Construction, rigging, material handling

Size : Customizable, standard sizes available

Color : Silver/Grey

Webbing Sling

Price 700 INR

Minimum Order Quantity : 1 Piece

Capacity : 500 kg to 10,000 kg (varies by sling size and type)

Application : Construction, shipping, warehousing, industrial material handling

Size : Available in multiple lengths and widths (customizable as per requirement)

Color : Purple, Green, Yellow, Red, Blue, Orange (colorcoded based on capacity)

|

SHIVAM ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry